Filling Vial in Grade A Environment

This document provides a comprehensive overview of the procedures and considerations involved in filling vials within a Grade A environment. A Grade A environment is crucial in pharmaceutical and biotechnology industries, where the sterility of products is paramount. This document outlines the necessary steps, equipment, and best practices to ensure compliance with regulatory standards and maintain product integrity.

Introduction

Filling vials in a Grade A environment is a critical process that requires strict adherence to cleanliness and sterility protocols. This ensures that the final product is safe for use and meets the required quality standards. The following sections detail the essential components of this process, including the preparation of the environment, equipment used, and the filling procedure itself.

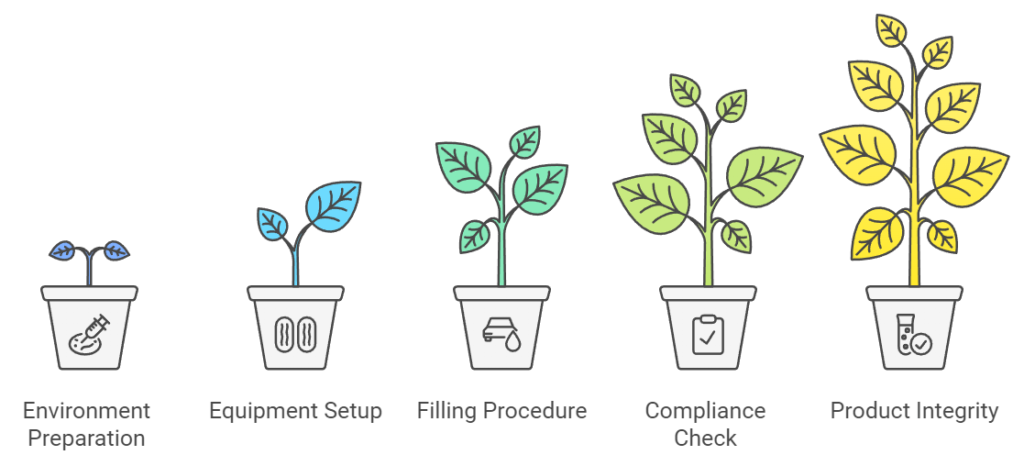

Preparation of the Grade A Environment

- Cleanroom Standards: Ensure that the filling area meets the ISO 14644-1 standards for a Grade A environment, which includes maintaining a maximum allowable particle count.

- Gowning Procedures: Personnel must follow strict gowning procedures, including wearing sterile gowns, gloves, masks, and hair covers to minimize contamination risks.

- Equipment Sterilization: All equipment, including filling machines, vials, and tools, must be sterilized using appropriate methods such as autoclaving or using ethylene oxide.

- Airflow Management: Utilize laminar airflow hoods or isolators to maintain a sterile environment during the filling process. Regular monitoring of airflow patterns is essential.

Equipment Used in Vial Filling

- Filling Machines: Automated or semi-automated filling machines designed for sterile environments are preferred to minimize human intervention.

- Vial Washers: Prior to filling, vials should be thoroughly washed and sterilized to remove any contaminants.

- Sealing Equipment: Ensure that the sealing equipment used for vials is also sterilized and capable of providing a secure, sterile seal.

- Monitoring Systems: Implement environmental monitoring systems to continuously track particle counts, temperature, and humidity levels within the Grade A area.

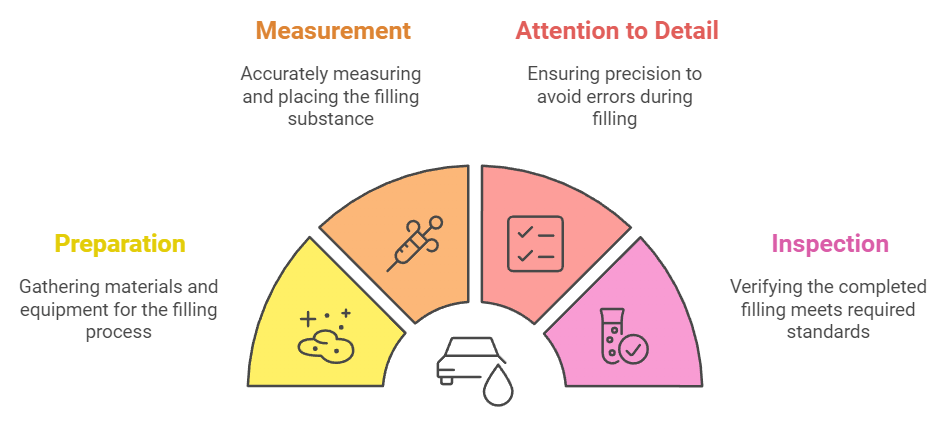

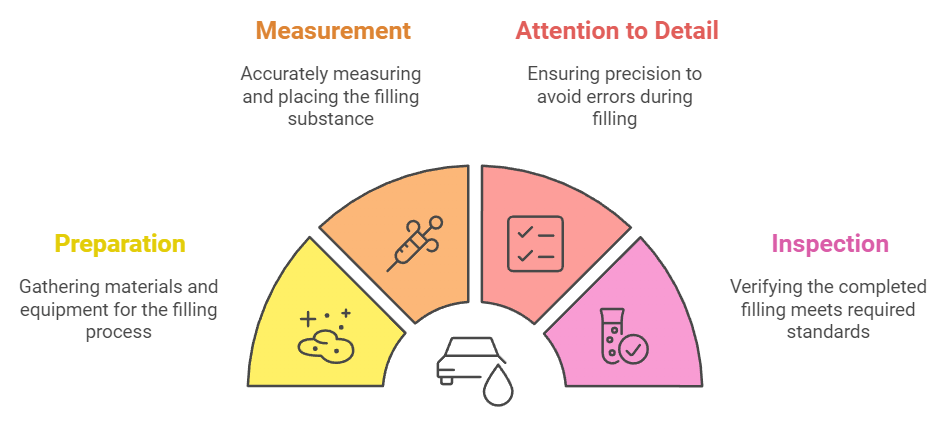

Filling Procedure

- Pre-Filling Inspection: Conduct a thorough inspection of vials and equipment to ensure they are clean and free from defects.

- Filling Process:

- Begin the filling process by transferring the sterile product into the filling machine.

- Monitor the filling volume and ensure that it meets the specified requirements.

- Minimize the time that vials are open to the environment to reduce contamination risks.

- Post-Filling Handling: After filling, vials should be immediately sealed and labeled. Ensure that the sealing process is performed in a sterile manner.

- Documentation: Maintain accurate records of the filling process, including batch numbers, equipment used, and personnel involved, to ensure traceability and compliance with regulatory requirements.